Certifying as a B Corporation goes beyond product. B Corp Certification is the only certification that measures a company’s entire social and environmental performance. The B Impact Assessment evaluates how your company’s operations and business model impact your workers, community, environment, and customers.

Requires that the responsible persons and, under certain circumstances, the distributors of cosmetic products submit some information about the products they place or make available on the European market through the CPNP.

Product designers, manufacturers and brands around the world rely on the Cradle to Cradle Certified Product Standard as a transformative pathway for designing and making products with a positive impact on people and planet. From fragrances to flooring, t-shirts and jeans to water bottles and window treatments, thousands of products are Cradle to Cradle Certified. What’s more, a growing number of brands, organizations and standards also recognize Cradle to Cradle Certified as a preferred product standard for responsible purchasing decisions.

ECOCERT is an organic certification organization, founded in France in 1991. It is based in Europe but conducts inspections in over 80 countries, making it one of the largest organic certification organizations in the world. ECOCERT primarily certifies food and food products, but also certifies cosmetics, detergents, perfumes, and textiles. The company inspects about 70% of the organic food industry in France and about 30% worldwide. ECOCERT is also a leading certifier of fair trade food, cosmetics and textiles as per ECOCERT Fair Trade standards.

Good Manufacturing Practice (GMP) is a system for ensuring that products are consistently produced and controlled according to quality standards. It is designed to minimize the risks involved in any pharmaceutical production that cannot be eliminated through testing the final product.

The Ministry of Food and Drug Safety established a food safety management system to provide safer food. Domestic foods are managed through three stages: manufacturing, distribution, and consumption. In the manufacturing stage, the business operator must first submit a food manufacturing and item manufacturing report. In the manufacturing stage, self-quality inspections are conducted to ensure safety of products, and the HACCP system is applied to protect food from any hazardous risk in a preemptive manner. In the distribution stage, food products are collected and inspected to strengthen safe food distribution, and the food traceability system is operated to trace the distribution routes of harmful foods, along with the operation of the Hazardous Food Sales Prevention System. In the consumption stage, false or exaggerated advertisements are monitored and consumer food sanitation guard system is operated.

The Food and Drug Administration (FDA) is the national health product regulatory agency created by Republic Act (RA3720), as amended by Executive Order No. 175 and RA 9711. FDA regulates the drugs, medical devices, food, cosmetics and toys, and Household/Urban Hazardous substances. The mission is guaranteeing the safety, quality, purity, efficacy of products in order to protect and promote the right to health of the general public.

HET-CAM test (hen’s egg-chorioallantoic membrane test) is a test used to determine the irritation potential of substances and is an alternative test to the Draize Rabbit Eye Test. In the test, incubated hen’s eggs are opened carefully on day 9 and the chorioallantoic membrane (CAM) is exposed.

Microbiology testing services help minimize the risk of potential damage by microbes and to ensure the microbiology quality of your products is maintained. While many are harmless, some can cause severe illness or contaminate sterile environments. Microbial testing is necessary and required by many industries worldwide, where human health is at risk of being adversely affected by biological pathogens, disease-causing bacteria, and other toxins.

Dermatologically tested can mean testing anything listed under the medical practice of Dermatology. At its most basic, it means that the product was tested by or in consultation with a dermatologist for tolerance and signs of obvious or severe skin reactions. Dermatologically tested may mean that a doctor of dermatology may or may not have been in charge of the tolerance tests that were carried out on voluntary test persons while using the product. The generally accepted meaning for ‘dermatologically tested’ relates to the following claims:

- That the product has been tested on human skin

- That the formula has been found to be mostly safe when applied to the skin

- That the finished product was well tolerated by persons who tested it on their skin, and in most cases, it did not cause skin reactions

A patch test is a simple way of checking whether your skin will react to new products such as cosmetics, soaps, moisturizers or topical medications. Patch testing is a common way to check for a variety of allergies.

A challenge test is a procedure in which a product is challenged by exposure to specified types of bacteria and fungi to determine whether it is adequately preserved. Assessment of preservative efficacy is needed over the intended shelf-life of that product. Test organisms should be representative of those likely to occur as contaminants during use and should consist of Gram-positive and Gram-negative bacteria, mould and yeast. In-house factory isolates obtained as a result of contamination of earlier batches of a product may also be included.

The goal of stability testing is to demonstrate “how the quality of a product substance or product varies with time under the influence of a variety of environmental factors, such as temperature, humidity and light.” To support a stability study, analytical methods using HPLC, LC/MS and GC are used to test for degradation products apart from tests to determine the sterility of the substance and whether the container or packaging of the final commercial product is compromised.

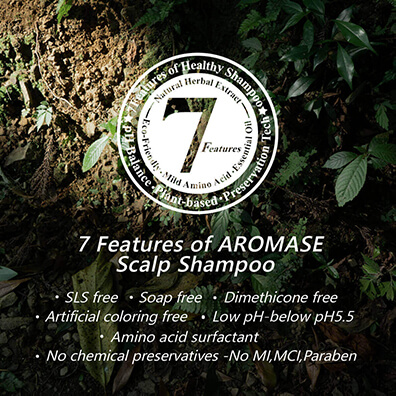

A label that says ‘no preservatives’ usually isn’t referencing the natural substances. Most of the time, what manufacturer’s mean is that no chemical preservatives have been added. These include such chemicals as BHA (Butylated hydroxyanisole) and BHT (butylated hydroxytoluene).

Artificial colours are made in labs, these are chemical substances that are developed to enhance the appearance of food by giving it artificial colour. Food colourings have been used for centuries now. Earlier they were created from coal tar, nowadays they are made with petroleum.